Enel, worldwide training program for site maintenance using Virtual Reality experience

Transformative innovation

Energy & Utilities

Enel

2019

Challenge

To rethink employee training processes from a digital and virtual perspective. To offer a learning method that complements traditional in-person training, which until now has always been carried out at Enel’s maintenance training centers.

Solution

An immersive virtual reality solution that is efficient, cost-effective and scalable. It is meant to standardize and streamline training processes, keeping track of progress and providing instant feedback on how the training process is going.

Impact

The solution enables training centres to safely bring network maintenance experience to life by simulating high-risk situations. The repeatability of the experience, the standardisation and uniformity of the training and the potential for error tracking, combined with the experience of the trainer being present to guide the user, makes it a valuable tool to complement more traditional teaching and field trials.

However, there is only a limited number of learning centers, which is why it was necessary to explore alternative and parallel ways of ensuring that training is scalable, accessible and widespread, combining virtual training with traditional in-person training.

Just like many other 3D-related technologies, Virtual Reality has experienced exponential growth in terms of device distribution and use in a wide range of sectors. This technology allows settings to be recreated and everyday actions to be simulated as well as many other scenarios.

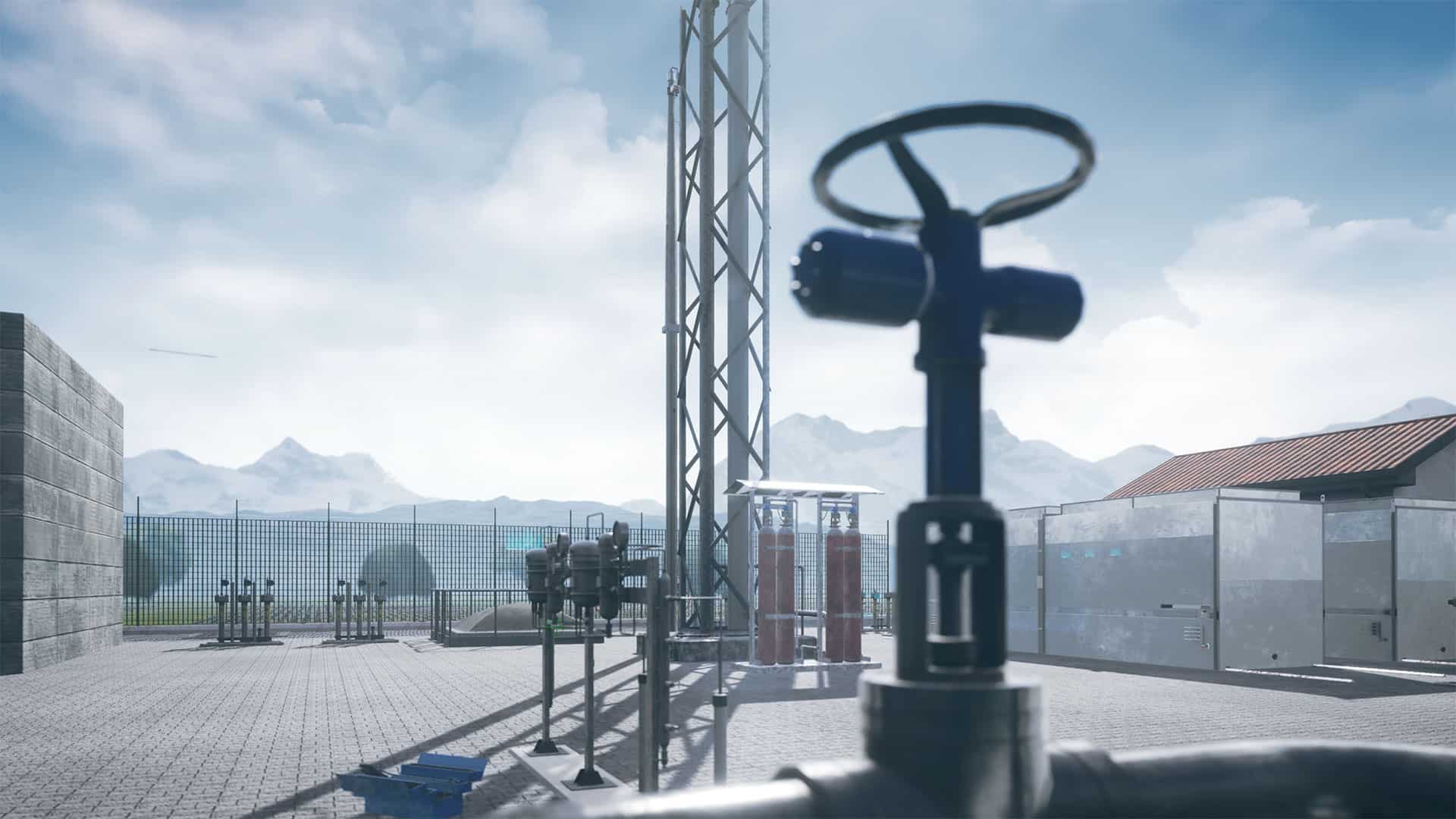

In an effort to rethink the training experience, we developed a Virtual Reality simulator to safely test operations in critical environmental conditions and other complex and dangerous procedures, thus evolving the learning approach.

After establishing the hardware and logistical requirements, we defined the first set of procedures to be simulated. By visiting the physical locations involved in the procedures, we were able to design and define a detailed storyboard for each scenario, simulating a true-to-life setting.

The next step was to design and build the settings and 3D interactions. Once the first Virtual Training centers were set up, along with a digital content distribution system to speed up the download process, we provided a catalog of training experiences and scenarios available with different levels of difficulty and of environmental and climatic risk, all in one VR setup.

Enel’s expertise in terms of safety procedures of energy networks and our team’s ability to imagine new interactions resulted in an immersive virtual reality simulator that quickly took the form of a digital school camp for training centres. From an initial experiment in the Italian home territory, this innovative training mode was soon exported first to Romania, then to Brazil, Chile and Colombia, before being extended to other business units such as Enel Green Power.